Why Join SU

Swakop Uranium is a shareholding partnership between the Republic of Namibia and Peoples Republic of China, based on a long-standing brotherly relationship between the two countries.

We seek highly energetic graduates to join us, we shall provide you with the best training and experience and you may then be part of the future leadership of the Mine.

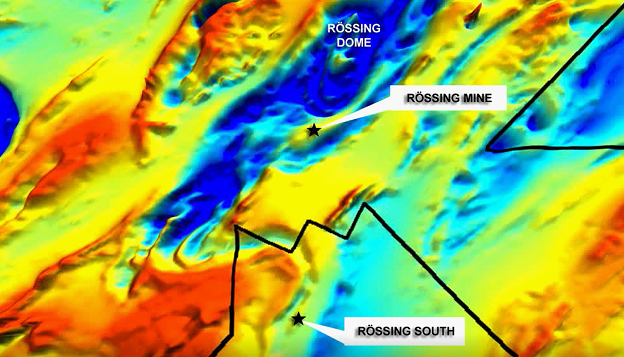

The Husab Mine is now in operation and destined to be a national icon for Namibia based on its size and contributions to the nation and FISCUS. The Mine is the largest employer in the Mining Industry in the country. And its unique business model underpins the long standing of its operations.

Whether you are starting your career as a graduate, or looking to move to the next level, SU offers a challenging work environment and exciting career development opportunities that will make you a competitive contender in the labour market. We embrace our multinational workforce to develop highly disciplined, diligent, dedicated and developed employees who excel in a high performance culture.

When you join SU, you will be joining a global giant and a powerful network of talented mining professionals.

Our core value “Doing things right in one go” defines our norms that guide us in our daily work in order to fufill our mission and vision. Doing things right the first time at every step, every process and every stage conforming with “Safety First, Quality Foremost and Pursuing Excellence” will make you one of the professional elites of the country.

We provide great opportunities to build lifelong connections with colleagues and clients all around the world. There are exciting projects to make the Company a world class operation based on business principles that centre on quality, standards, financial acumen and good people skills.

We offer competitive salary packages with benefits such as medical aid, provident fund benefits, 24-hour insurance cover in case of accidents, social security and annual performance bonus.

SU is devoted to people’s development and provides high achievers with opportunities to grow professionally in the form of study benefits and study related leave.

If you are a highly disciplined, diligent, dedicated and developed team player, an individual who has the ability to make decisions and solve problems quickly, a professional who can plan, organize and prioritize work and who has advanced technical knowledge and excellence of work in your respective fields, please let us know, we will bring out our finest tea to welcome you!